There’s nothing like the warmth a scarf provides during frigid winter weather, keeping you safe from the cold when you venture outside. Whether you’re simply running errands or headed to a sporting event, you can’t leave home without your scarf this time of year.

Businesses, sports teams, and event organizers are starting to realize just how much power a customized scarf brings from a branding perspective, too. These are a practical way to get your logo in front of more eyes. That’s why we’ve created this guide on how to make a scarf.

We’ll walk you step-by-step through how to make scarves on your own since this is such a popular DIY project, but the truth is, there’s no need to toil through the challenges of making scarves yourself when a better solution is just a few clicks away.

Diehard Custom makes it quick, easy, and affordable to bring your custom scarf vision to life. We’ve earned the trust of small businesses and massive organizations alike over the past decade by consistently exceeding expectations for quality and service.

So, learn more about how to knit a scarf DIY below, and why when it comes to where to make a custom scarf the easy way, Diehard Custom is the no-brainer choice!

Why Make Your Own Scarves?

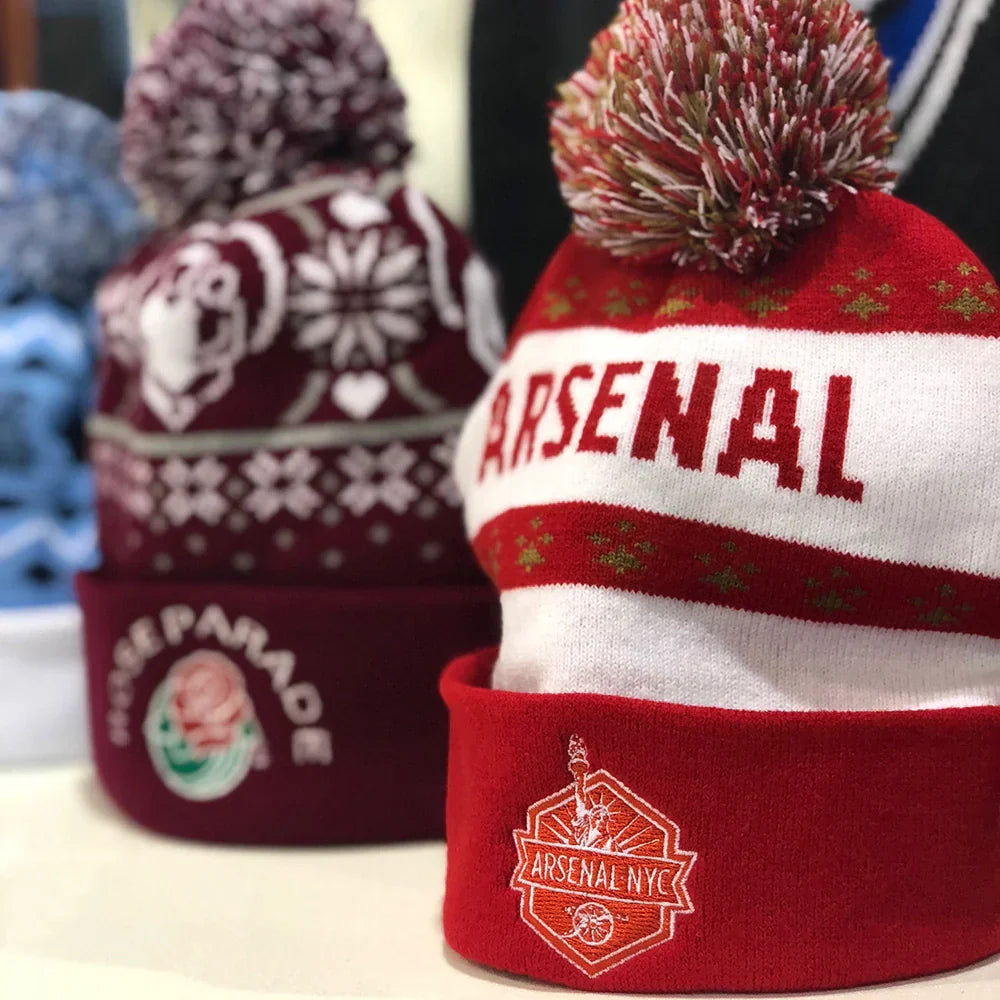

Whether for personal use, business promotions, or team apparel, making your own scarves is a great use of time and resources. In fact, this may be a better approach than the more common custom hats with logo or custom socks with logo you’re used to seeing.

In general, making your own scarves gives you complete control over the style, colors, and design elements to match your exact needs. You can make sure you stand out among a sea of competitors.

But what really makes custom scarves such a great investment in your brand or team is the balance between functionality and style they provide. Here are some common uses for custom scarves:

- Corporate Swag Giveaways: A professional, high-end alternative to traditional promo gear. Stay top of mind with vendors and clients by sending them something outside of the norm.

- Team and Organization Apparel: Helps teams, clubs, and companies look polished and cohesive out and about. This is really great for events where you want staff members to be easily identifiable.

- Retail and Fundraising Merch: Popular for sports teams, schools, and nonprofits looking to raise funds by offering branded products in their shops.

Scarves can be branded without feeling overly promotional since you can design them with custom embroidery, woven designs, and sublimation printing. They’ll get worn time and time again, serving as a walking advertisement for your brand.

Although they’re primarily known for winter wear, lightweight scarves actually work great across seasons. There are stylish, breathable options perfect for layering in milder weather. Sports fans will wear these in any season to show team pride.

Plus, let’s be honest - the idea of learning how to make a scarf DIY sounds like a lot of fun! While we’ll show you how to knit a scarf below, just remember there’s a more simple, seamless approach to creating custom scarves, right here at Diehard Custom.

How to Make a Scarf DIY: Step-by-Step Guide

If you have knitting or sewing experience, or don’t mind going through a bit of trial and error, learning how to make scarves DIY can be a fun, fulfilling project. Does it make sense for brands or sports teams? Not really. You have better things to focus on.

But if you’re just trying to make a few custom scarves for friends and family, this approach might make sense. Be clear, though, you should set your expectations about how much you’ll be able to customize the scarves and how durable the final product will be.

Nevertheless, here’s how to make a scarf DIY.

Step 1: Choose Your Scarf Material

First things first, figure out what fabric you want to craft your scarves from. This sets the stage for the entire project, influencing comfort, durability, and appearance.

Remember, some materials are great for winter warmth while others are more lightweight and breathable for milder weather. Here are some popular DIY scarf materials:

- Fleece: Soft, warm, and doesn’t fray. Easy to work with for beginners.

- Cotton: Lightweight and breathable. Ideal for fashion scarves.

- Wool: Provides maximum warmth but can be itchy if not blended with softer fibers.

- Silk: Elegant and lightweight but requires delicate handling and hemming.

- Acrylic or Polyester Blends: Affordable and hold color well but may lack the softness natural fibers are known for.

Thicker fabrics like fleece or wool work best for winter scarves, while silk and cotton are ideal for lightweight accessories. What matters most is the quality of the material, as you don’t want to deal with pilling or fading over time. Invest in quality from the start.

Step 2: Select a Scarf Style

There are so many different scarf styles you can choose from when designing your own. While it mostly comes down to personal preference, different scarves do offer slightly different functions as well.

For example, infinity scarves feature a looped design that can be doubled around the neck for warmth and ease of wear. Fringed scarves, on the other hand, are more stylish with knotted or tassel-like fringe on the ends.

A standard rectangle scarf is the most versatile option as far as wrapping and styling flexibility goes. There are also square scarves, though, which can be folded into a triangle and worn around the neck for fashion purposes as well.

Ask yourself, is the scarf primarily going to be worn for warmth, style, or branding purposes? You should account for varying difficulty levels in learning how to knit a scarf as well. Infinity scarves, for instance, need precise measurements and clean stitching.

Step 3: Measure and Cut Your Fabric

Once you’ve landed on a style and have all your fabric on hand it’s time to get to work. Here are some general scarf measurements:

- Standard Scarves: 60-80 inches long x 6-10 inches wide.

- Infinity Scarves: 55-75 inches in circumference x 8-12 inches wide.

- Square Scarves: 36 x 36 inches (adjustable based on preference).

They say measure twice, cut once, and that’s not something you should take lightly. The last thing you want is to have to head back to the store to buy more material because you cut your scarf too short.

Use fabric scissors or a rotary cutter for clean cuts along the edges as this will provide a more professionally made look. You might want to use chalk or tailor’s pencils to put light marks on the fabric, guiding your cuts and helping you maintain straight lines.

If you’re using a patterned fabric it’s important to align the print properly to prevent uneven designs. Any mistakes here will impact the way your scarf looks in the end, so take your time.

Step 4: Sew or Finish the Edges

Finishing the edges prevents fraying and gives your scarf a polished look you’ll be proud to show off. There are a few different methods you can use depending on the material in question and the desired aesthetic.

- Basic Hem: Fold edges inward twice and sew for a clean, classic finish.

- Overlock Stitch (Serger): A durable stitch that prevents fraying in cotton or wool.

- Rolled Hem: A delicate stitch for lightweight scarves like silk.

- No-Sew Method: For fleece scarves, simply cut with pinking shears to create a decorative edge.

Another option we referenced earlier is the fringed scarf, but that’s far more involved so we’ll recommend sticking to the basics for now since you’re just learning how to make a scarf DIY.

Step 5: Add Customization

Now comes the real fun of learning how to make scarves: customizing them with your own personal touches. This is where you can add a logo, a monogram, or anything else you can envision. There are a few classic approaches to adding customizations on scarves:

- Hand Embroidery: Time-consuming but great for one-of-a-kind pieces.

- Fabric Paint or Stencils: Easy for simple designs but may fade over time.

- Iron-On Vinyl: Fast but prone to peeling and cracking.

Each method has its pros and cons so be sure to think about which makes the most sense for your specific scarves. There is no right or wrong answer.

Step 6: Final Touches and Care Instructions

Most of the hard work is done now, it’s just a matter of putting the finishing touches on your scarf and moving on to the next one! Trim any loose threads or excess fabric, and lightly iron (depending on the fabric) the scarf for a smooth, flawless finish.

Add fringes, tassels, or decorative elements if desired, and there you have it, you know how to make a scarf DIY! Here are some tips to care for your scarves and keep them looking as good as they did the day you made them:

- Hand-wash or machine-wash based on fabric type.

- Use gentle detergents to maintain color and softness.

- Store properly to prevent wrinkles or stretching.

The only thing left to do now is get to work - unless, of course, you’ve decided you’d rather leave all this to the professionals so you can guarantee a high-quality scarf that will stand the test of time and bring benefits to your brand, team, or organization.

If that’s the case, then you’ll need to figure out where to make a custom scarf. Look no further than Diehard Custom.

Where to Make a Custom Scarf for a Seamless Experience and Exceptional Products

We know you came here hoping to learn how to knit a scarf or weave something together on your own, but the truth is, this is just not practical for anything besides a one-off project. Even if you just need 25 scarves, it makes more sense to get the job done professionally.

Challenges in the DIY Scarf Process

You can probably see why very few actually go through with the DIY scarf-making process. It’s time-consuming and taxing on your fingers when you’re making multiple. But there are also quality concerns to consider. Here’s why you may not want to make your scarves DIY:

- Inconsistent Sizing and Finishing: Measuring and cutting fabric by hand might lead to uneven edges and inconsistent dimensions. Lackluster sewing skills and finishing techniques can compromise the end result, too.

- Limited Customization Options: You won’t have nearly as much personalization potential with DIY scarves. Iron-on transfers, fabric paint, or hand embroidery lack the precision and durability of professional woven-in designs or high-quality embroidery.

- Wasted Time: If you run a business, sports team, or non-profit organization, you can probably think of better things to do with your limited time than handcrafting scarves DIY. This is simply not feasible for bulk orders.

A trusted custom scarf provider puts these challenges in the past and provides premium products you’re proud to attach your brand name and logo to.

You can rest assured the scarves are crafted to stand the test of time, all without lifting a finger! If you’re still wondering where to make a custom scarf, learn why Diehard Custom is the #1 choice below.

Why Make Custom Scarves at Diehard Custom?

Diehard Custom has helped thousands of companies bring their custom scarves to life over the past 10 years and counting. Over that span, we’ve earned a reputation for consistently going above and beyond, both in terms of scarf quality and customer service.

We use durable, soft-touch fabrics that maintain their shape and feel season after season. Whether you need warm knit scarves for winter or lightweight options for year-round wear, we’ve got the blank scarves you need to serve as a canvas for creation.

You can choose a style from our collection and then upload your logo and brand colors. If you don’t have a full design in mind already, our team will work with you to create one. With more than 80 yarn colors available the possibilities are endless!

With minimum order quantities (MOQs) as low as 25, even small teams or brands can design their own custom scarves with us. But the more you buy, the more you save, with prices as low as $4.29 for bulk orders!

We provide digital proofs for approval before production begins so there are no surprises, and we’re happy to send you a free sample so you can get a better sense of what sets us apart from the rest before committing.

How to Customize Scarves in a Few Clicks

It’s quick and easy to bring your vision to life with us on your side. Here’s how to make a scarf at Diehard Custom:

- Select Your Scarf Type: Choose from knit scarves, woven scarves, or sublimated polyester scarves based on your needs and desired look.

- Upload Your Logo or Artwork: High-resolution vector files (.AI, .EPS, .PDF) translate best into clean, professional-quality designs. Our team can help refine your logo so it integrates well with fabric.

- Choose Colors and Customization Method: Woven designs knit your logo directly into the fabric for a seamless, lasting look. On the other hand, embroidery and patches are great for high-detail logos or multi-layered textures. Sublimation printing supports vibrant, full-color designs with smooth detailing.

- Approve Your Design Proof: You’ll get a digital proof for review before production begins so you can confirm logo placement, colors, and details.

- Production and Delivery: Scarves go into production upon approval, taking 2-4 weeks to complete. You can rush delivery if need be. Orders ship directly to your business, team, or event, arriving on time and ready to wear.

It’s that easy, and you have access to personalized support from A to Z. With a satisfaction guarantee, it’s clear that you needn’t look further for where to make a custom scarf. Get started today at Diehard Custom.

Parting Thoughts on How to Make Scarves

Custom scarves are one of the best ways to showcase your brand, unify a team, or produce stylish, functional merchandise that moves the needle for your business. It’s just a matter of figuring out how to make a scarf: DIY vs professional customization.

We’ve walked you through how to make scarves both ways, so ultimately, the choice is in your hands. It’s clear that partnering with a professional is the way to go. So now that you know where to make a custom scarf, take the next steps at Diehard Custom.

You can also explore our blog for more swag ideas like how to make custom socks or the average price of a hat if you’re interested in rounding out your offerings. Otherwise, it’s time to get started designing custom scarves in a few clicks right now.

Don’t settle for anything less than the best for your brand, team, or organization. Bring your custom scarf vision to life today at Diehard Custom and see what keeps clients coming back for more!